Go with the flow

From idea to production: unlock the true potential of your chemistry with AM Technology’s Flow Reactors

Introducing Flow Chemistry: Revolutionizing Reactions in the Lab

Are you tired of the limitations and inefficiencies of traditional batch reactors? It’s time to embrace the future of chemical manufacturing with flow chemistry. Flow reactors offer a groundbreaking approach that enhances the efficiency, scalability, and safety of reactions in the pharmaceutical and life science industry. Join the scientific revolution and discover the power of flow chemistry!

Efficiency at Its Finest

Gone are the days of interrupted reactions and time-consuming cleaning processes. Flow chemistry enables continuous mixtures without any interruption, ensuring smooth and seamless workflows. With precise control over crucial reaction parameters such as heat transfer, mixing, and reaction time, flow reactors bring unparalleled efficiency to your lab. Say goodbye to yield losses and hello to better outcomes.

Versatility Unleashed

Flexibility is the name of the game in modern chemical manufacturing, and flow chemistry delivers in spades. Embrace the versatility that flow reactors offer, allowing you to mix multiple liquids simultaneously, eliminate cleaning between processes, and achieve higher productivity. Whether you’re in the R&D, pilot, or production phase, flow reactors adapt to your needs and enable seamless scalability.

Your success is our priority

Thanks to a dedicated team of engineers and scientists at Optimus and AMT, you enjoy an array of services which ensure a seamless transition to and optimisation of your processes:

- Continuous Process and R&D optimisation: our experts work closely with you to develop and optimise your processes, improving efficiency and achieving desired results.

- Technology transfer from Batch to Flow: Do you have an existing batch process? Our skilled chemists can work with you to convert it into flow, making the process more efficient and reducing reaction time. Through extensive testing and optimisation, we ensure a smooth transition that maximises the the benefits of Flow Chemistry

- Scalability trials and feasibility studies: with the Coflore range of reactors, you can easily scale up your chemical processes from laboratory to pilot-plant and production. Our team of experts can guide you through the scale-up process, proving invaluable insights and support.

TLDR? here are the 9 key advantages of Flow Chemistry!

- Improved heat transfer and mass transfer/mixing ensure optimal reaction conditions, enhancing product quality and purity.

- Reproducibility becomes a breeze, thanks to the precise control over reaction parameters, enabling consistent results every time.

- Easier route to scale-up allows you to seamlessly transition from R&D to pilot to production phases, saving you time and resources.

- Multistep reactions are simplified with telescoping, enabling the integration of multiple processes into a single continuous flow, maximizing efficiency.

- In-line downstream processing streamlines your workflow, reducing manual handling and improving overall productivity.

- Automation takes center stage, empowering you to optimize your processes and achieve unparalleled efficiency.

- Enhanced safety management ensures the well-being of your team by effectively handling hazardous reagents and intermediates.

- Smaller reactor footprints save valuable lab space, maximizing your efficiency and productivity.

- Lower operational costs, reduced solvent use, and minimal fugitive emissions make flow chemistry an environmentally friendly choice.

Choose the perfect flow reactor for your needs

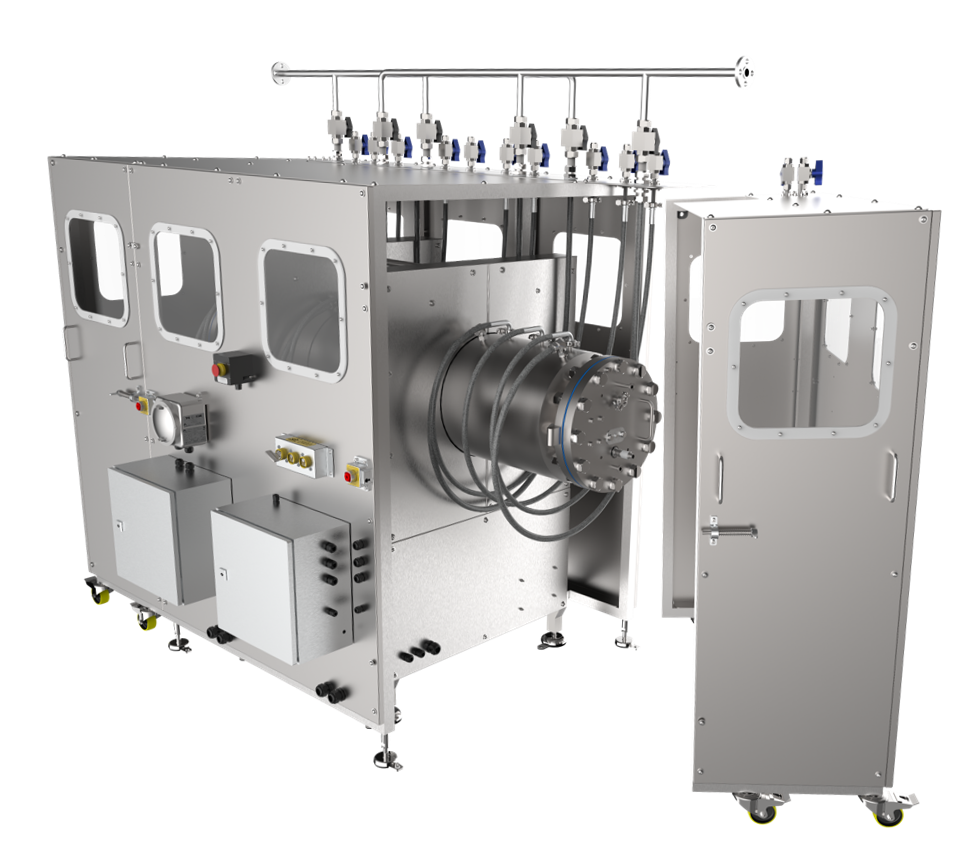

Laboratory Scale Flow Reactor

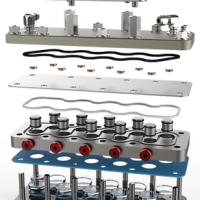

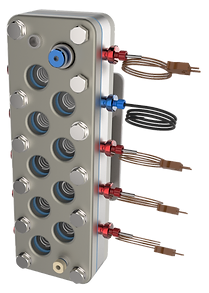

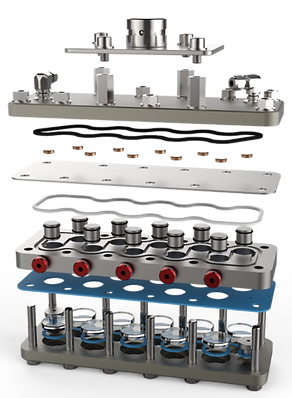

Perfect for both R&D and Kilogram scale production, the Coflore ACR is a dynamically-mixed flow reactor. It offers exceptional flexibility with 10 CSTRs (continuous stirred tank reactors), providing ultimate control and adaptability for both single-phase and multi-phasic reactions. Whether it’s route scouting, scale-up, catalyst screening, or process development, the Coflore ACR has got you covered.

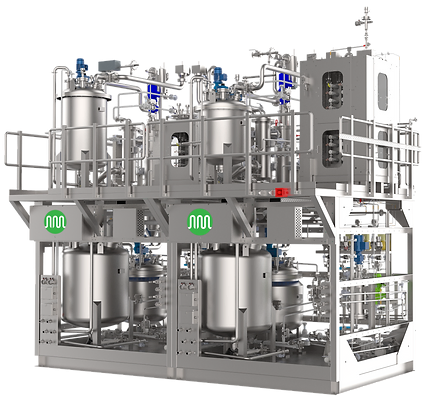

Pilot / production Scale Flow Reactor

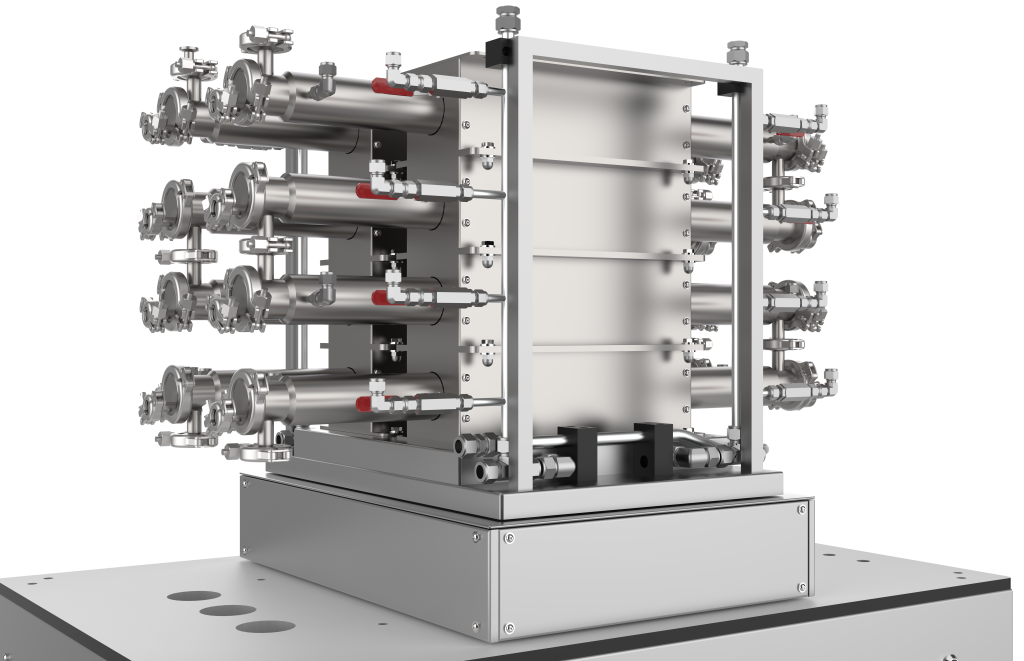

When it comes to kilogram and tonne scale production, the Coflore ATR is your go-to solution. With the capability to vary the number of reactor tubes, scaling up production becomes a breeze. Featuring up to eight reactor tubes, each independently heated or cooled, this pilot-plant continuous process reactor ensures efficient and reliable performance. It handles single- and multi-phase reactions, even dense slurries, without any risk of blockage.

Production Scale flow reactor

The Coflore Rotating Tube Reactor (RTR) is the final boss in our lineup. It has a capacity of 100 L and is capable of processing countless reactor volumes without interruption. For a 5-minute residence time, the RTR can produce 1,200 L per hour or 28,800 L per day! Contact us directly for more information on the Coflore RTR.