Is your testing lab ready for the EV transition?

Electric vehicles have fewer moving parts, incorporate different materials and operate under conditions that are different from those of an internal combustion engine. They do however still require a number of fluids and coolants to operate, which need to be engineered (and tested) to meet the new specifications.

Is your lab ready to handle the transition?

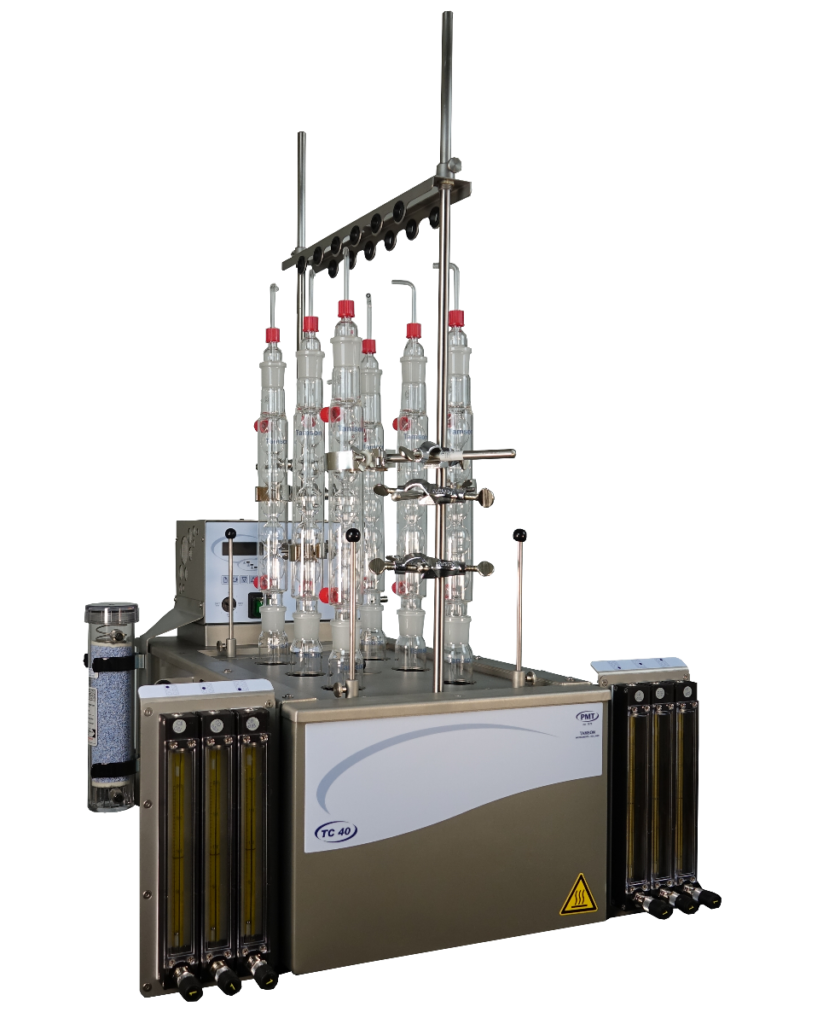

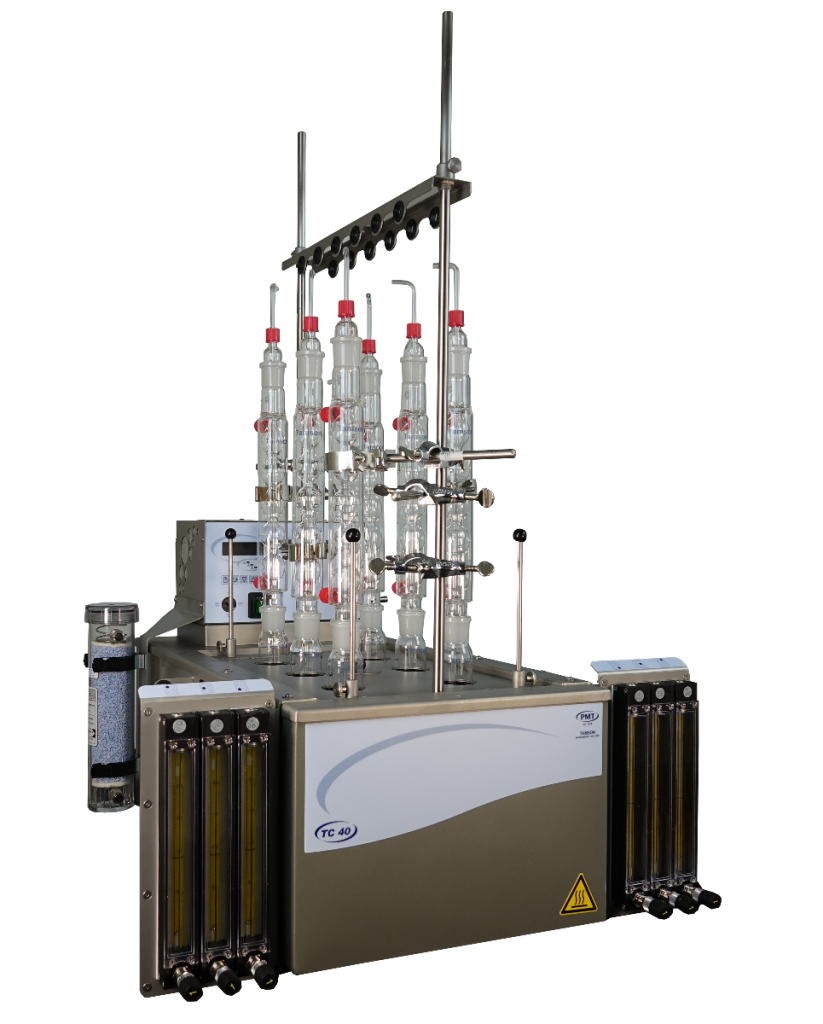

Oxidation stability

The CEC L-48-00 is your companion to test the next generation of electric driveline fluids. By artificially aging lubricating oils, you can determine their resistance to high temperature oxidation and to resist oil degradation or sludging.

The samples are tested for kinematic viscosity change and infra-red spectroscopy (FTIR) and compared to fresh oil. The process takes place in a stainless bath with precise (0,02°C) temperature control and large (thus stable) reservoir. Featuring six test positions and calibrated flow meters, this is the ultimate oxidation stability testing platform.

ASTM D892 Foaming test

The tendency of oils to foam can cause serious problems in systems such as high-speed gearing, high volume pumping or splash lubrication. With inadequate lubrication or cavitation leading to mechanical failures, it is vital to test the foaming characteristics conform ASTM D892.

This dual foam bath setup has 2 test positions per cylinder and can be equipped with an optional dryer and digital mass flow meter, offering even finer readings and adjustments. Adding ASTM D6082 is possible with a custom-made configuration.

Corrosion test

Fluids and coolants for hybrid, fuel cell and battery vehicles will soon be subjected to new specifications regarding their physical, chemical and performance requirements.

During a corrosion test, both engine coolants (according to ASTM D1384) and heat transfer fluids (in accordance with ASTM D8040) are introduced to specific set of metals, while keeping them in glassware at a stable temperature.

This six position stainless bath/circulator can reach up to 250°C with extremely stable temperature control and is your one-stop shop in corrosion testing.