Art nr FG-K19026-KW

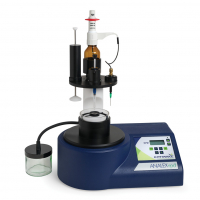

Analex rpd

Metallic Wear Particle Depositor

The Analex rpd Particle Depositor offers a rapid and simple method of debris separation. A measured volume of sample is applied, by pipette, to a glass substrate located on a rotatingmagnet assembly. Particles of debris are deposited radially as three concentric rings by the combined effects of rotational,

magnetic and gravitational forces.

BENEFITS

- Quick and easy to operate

- Low sampling costs

- Easy to use

METHOD

- No ASTM-standard applied

APPLICATION

A wear debris sample is generated by the Analex rpd and viewed under a microscope. This is used to identify particals of debris optical and electron microscope.

FEATURES

-Simple method of both ferrous and non-ferrous metallic debris separation, enabling you to effectively analyse the results of your oil sample

- Suitable for lubricating oils, hydraulic fluids and greases

- Supplied complete with a comprehensive ‘Guide to Wear

- Particle Recognition’

- Excellent particle separation - deposition path length is equivalent to a linear 160mm

- The separated debris can also be measured quantitatively by placing the substrate in an ANALEX PQ Ferrous Debris Monitor

- Rotational Speed: 30 - 200 rpm (4 preset speeds)

- Operating Temperature Range: 10°C to 30°C

- DC Power Input: 15 V DC

- AC Power Input to DC Supply: 100 - 240 V AC

- Display: Alphanumeric LCD

- Dimensions: 360 mm x 220 mm x 500 mm

- Weight: 4.5 kg

- No ASTM-standard applied

APPLICATION

A wear debris sample is generated by the Analex rpd and viewed under a microscope. This is used to identify particals of debris optical and electron microscope.

FEATURES

-Simple method of both ferrous and non-ferrous metallic debris separation, enabling you to effectively analyse the results of your oil sample

- Suitable for lubricating oils, hydraulic fluids and greases

- Supplied complete with a comprehensive ‘Guide to Wear

- Particle Recognition’

- Excellent particle separation - deposition path length is equivalent to a linear 160mm

- The separated debris can also be measured quantitatively by placing the substrate in an ANALEX PQ Ferrous Debris Monitor

- Rotational Speed: 30 - 200 rpm (4 preset speeds)

- Operating Temperature Range: 10°C to 30°C

- DC Power Input: 15 V DC

- AC Power Input to DC Supply: 100 - 240 V AC

- Display: Alphanumeric LCD

- Dimensions: 360 mm x 220 mm x 500 mm

- Weight: 4.5 kg

There are no accessories available for this product.

There are no consumables available for this product.