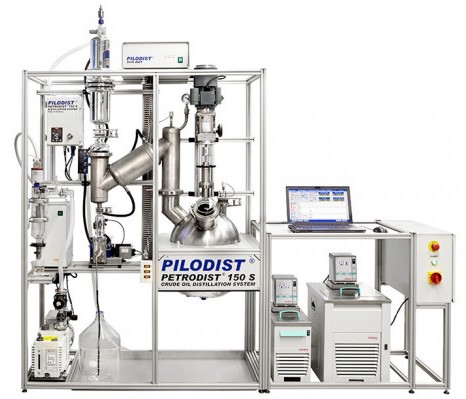

Crude oil fraction distillation and bitumen recovery

The processor controlled crude oil distillation system includes control of heating and vacuum as well as the display and storage of all important process values: The design is based on the distillation of a charge of 10 – 20 kg of crude oil in a minimum of time with a high throughput until a final temperature of 400 °C AET.

• Temperature of heating bath (PT 100)

• Temperature of product in flask (PT 100)

• Temperature of vapor (PT 100)

• Pressure of distillation (0-100Torr)

The crude oil is charged into a stainless steel flask and heated by an electrical heating bath. All vapors are passing through a stainless steel column and are condensed in an integrated vertical condenser. An additional high performance condenser which is located on top of the column construction is required to condensate all remaining light boiling components.

All condensed product is being discharged by means of a tempered gear pump into a tank (receiver) or a fraction collector. The discharge process is being performed independent from the current system pressure (atmospheric or vacuum) to avoid any manual discharge in between the different pressure conditions.

The whole processing of the distillation can be visualized all the time by glass connecting pieces, a viewing glass in the flask, condenser and glass intermediate discharge receiver, located between pump and column. The distillation is performed in several pressure steps (atmospheric and vacuum) until a final atmospheric equivalent temperature (AET) of 400°C. Once the final temperature is reached and distillation is finished the still heated residue in the flask can be discharged via a valve located at the bottom of the flask.