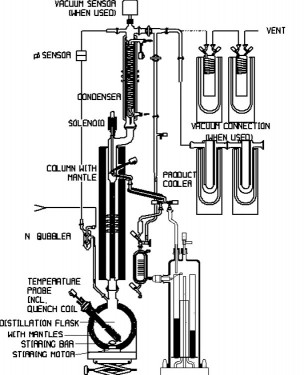

Crude Oil Distillation, Manual, TBP (ASTM D2892)

Computer controlled crude oil distillation system for semi-automatic operation according to ASTM D-2892.

The system is designed for automatic operation of the individual distillation stages, the fraction changes resp. the receiver changes are automatically carried out according to pre-selected boiling temperature or when the receivers are filled up. The vacuum-tight fraction collector contains 9 receivers. The receiver volume is related to the flask size.

There are 9 receivers for every distillation stage, thus max. 36 fractions can be obtained with the usual 4 distillation stages.

Distillation control device 4001

Computer-controlled Device for PILODIST Distillation systems with all necessary and peripheral components.

Contains the operation and control elements for all parameters like temperature, vacuum, reflux divider, limit and alarm system, fraction collector. The actual parameters can be displayed in graphical curves to inform the operator about the actual status. The set parameters can be saved as recipes and reloaded. The control system is based on a multifunctional serial bus system, connected to a PC with our new and most modern windows based operation software.

The distillation control device comes along complete with all operation software, PC and interface box as central connection point for all sensors.

The installation requires water, nitrogen, compressed air and electricity.

Operation temperature: up to 420 °C

Operation pressure: vacuum down to 1 Torr

Final Cut temperature : 400° C AET (750° F)

Max. ambient temperature: 25° C

Mains supply: 230 / 380 V, 50 Hz, 5-wire system, 3-phase + N + PE

Dimensions : depending on the flask size