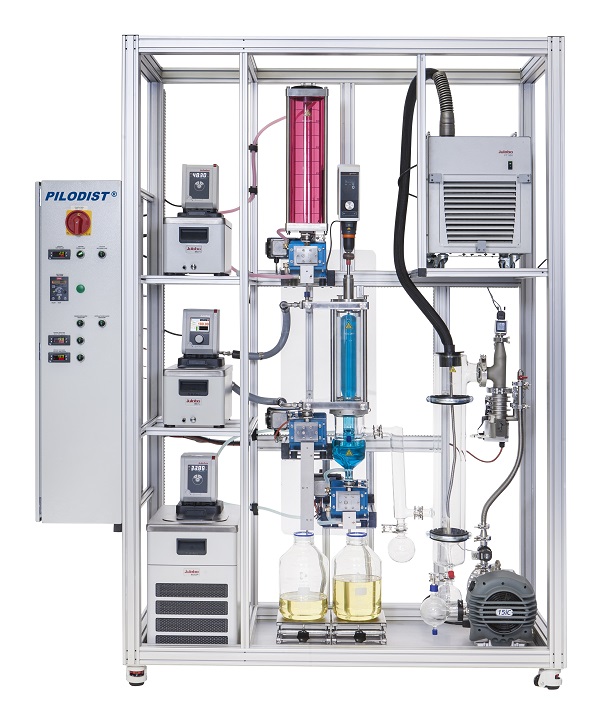

Molecular wiped film short-path distillation

Wiped-film evaporator for short-path and molecular distillation

The new flagship for short path and molecular distillation. The SP 1000 CC is a turnkey ready system for laboratory use and small scale production and is optimized to cover nearly all applications, from high melting to high boiling points and can handle thermal sensitive material, with full flexibility and complete continuous operation.

The molecular distillation, also called high vacuum wiped film, thin film or short path distillation, is a well-known process to separate thermal sensitive material in a very thin film at a high vacuum and short distance to the condenser, which allows an unbeatable performance.

The SP 1000 CC is equipped with a unique and patent pending HYBRID-evaporator which combines all positive aspects of glass and stainless steel in one instrument. It is reliable and solid like stainless steel, but with the full visibility of a glass still.

Due to its complete heated inlet and outlet lines in combination with our tempered feed- and discharge pumps, melting points >150°C can be easily handled.

The sophisticated vacuum system is able to handle incondensable volatiles with its dry running chemical resistant scroll pump as well as the air cooled diffusion pump can reach a system pressure down to 0.00001mbar.

Due to the fully vacuum tight feed and discharge system there is no limitation in the charge or receiver vessel size and the system can run up to 24/7 operation without any interruption in the vacuum process and a throughput up to 7l/h.

Special Advantages of the new SP 1000:

• Patent Pending Hybrid Evaporator

- Combines all the positive characteristics of glass and stainless steel

- Full visibility of the process

- Reliable and precise

- Lowest tolerances in the market (no welding, no forming)

- Easy cleaning

- lowest maintenance & repair costs due to changeable glass-cylinders

- complete heated inlet and outlet lines

- Lowest hold up due to extreme compact design

• High capacity glass condenser

- Reliable and strong design

- Easy removable for cleaning

- Full visibility

- Complete tempered

- Maximized surface and minimized distance to the evaporator

• Precise Vacuum control system

- Digital vacuum controller for high reproducibility in first pass

- Double vacuum sensor system

- No problems with incondensable vapors due to high capacity oil free scroll vacuum pump (15m³/h)

- Vacuum line in huge diameter for maximum performance and easy cleaning

- Automatic safety circuit for diffusion pump control

- Double condensate receiver system to separate light ends

- High capacity diffusion pump (65 l/s → 234m³/h) with oil level indicator

- Supersized vacuum cold-trap for outstanding vacuum performance

- Cold-Trap with drain nozzle for easy maintenance

- Optional electrical immersion cooler down to -90°C (no dry ice needed)

• Vertical design for optimized product flow without hold-up in useless pumping lines

• Hermetically sealed, high vacuum tight, tempered gear pumps for fully continuous operation

• Complete tempered discharge system without any solidification of heavy residues

• Sophisticated control cabinet for easy handling with “CULUS” approval

• All heating/cooling circuits with maximized diameter and minimized length for optimized heat transfer

Operating temperature : up to 200°C (250…350°C upon request)

Final pressure : down to 10-5 mbar

Feed range : approx. 1000-4000 ml/h, dep. on application

Evaporator surface : 1000 cm2, short path

Evaporator : borosilicate glass

Feed vessel : 5000 ml, graduated

Product receivers : variable (2000-5000ml, depending on model)

Speed range of stirrer : 30…1000 rpm

Dimensions (w x h x d) : 1750 x 2280 x 820 mm

Electrical Supply : 230/400V 25A 3L+N+PE (50Hz or 60Hz available)

The system consists of:

1 mobile mounting frame with all necessary holders and fastenings to accommodate all components, mounted on 4 wheels

1 graduated feed vessel, glass, volume 5000 ml, heated by circulation thermostat liquid flow, with complete heated inlet line, refillable also during vacuum operation for continuous working mode

1 circulating heating thermostat for heating of feed vessel and inlet lines, 4 l bath capacity, operating range +20°C... +150°C, heating capacity 2kW

1 hermetically sealed, high vacuum tight feed dosing pump, to transfer sample from atmospheric conditions into vacuum pressure, complete tempered

1 thin film-short path evaporator, made of glass, 1000cm2, with heated inlet and outlet lines and double mantle for thermal oil heating

1 High capacity cooling condenser, made of Borosilicate glass 3.3

1 wiper driver motor with adjustable speed up to 2000 rpm, driving shaft with flexible coupling and vacuum-tight lead through.

1 wiper basket, made of stainless steel AISI 316 Ti with PTFE wipers

1 thermostat for operating the short path evaporator, heating capacity 2 kW, operation temp. max. 200°C, with high performance circulation pump, isolated tubes, PID control and colour display.

1 vacuum sensor with integrated LCD-display for high vacuum application down to 10-5 Torr

1 vacuum sensor for precise control of vacuum levels 100 Torr – 1 Torr abs.

1 hermetically sealed, high vacuum tight distillate discharge pump, complete tempered, for continuous take-off without limitation of receiver size

1 hermetically sealed, high vacuum tight residue discharge pump, electrically heated, for continuous take-off without limitation of receiver size

1 set of sealings / gaskets / lines

1 special optimized vacuum system with diffusion pump and 15m³/h scroll pump as well as big vacuum cold trap including 3 condensate receivers

1 circulation cooling/heating thermostat, temperature range -20…+100°C to temper the condenser cooling finger inside the evaporator with 600W cooling capacity and 2kw heating power

1 electrical control cabinet with operating elements, vacuum controller, variable frequency drives for dosing pumps and power distribution for all connected equipment.