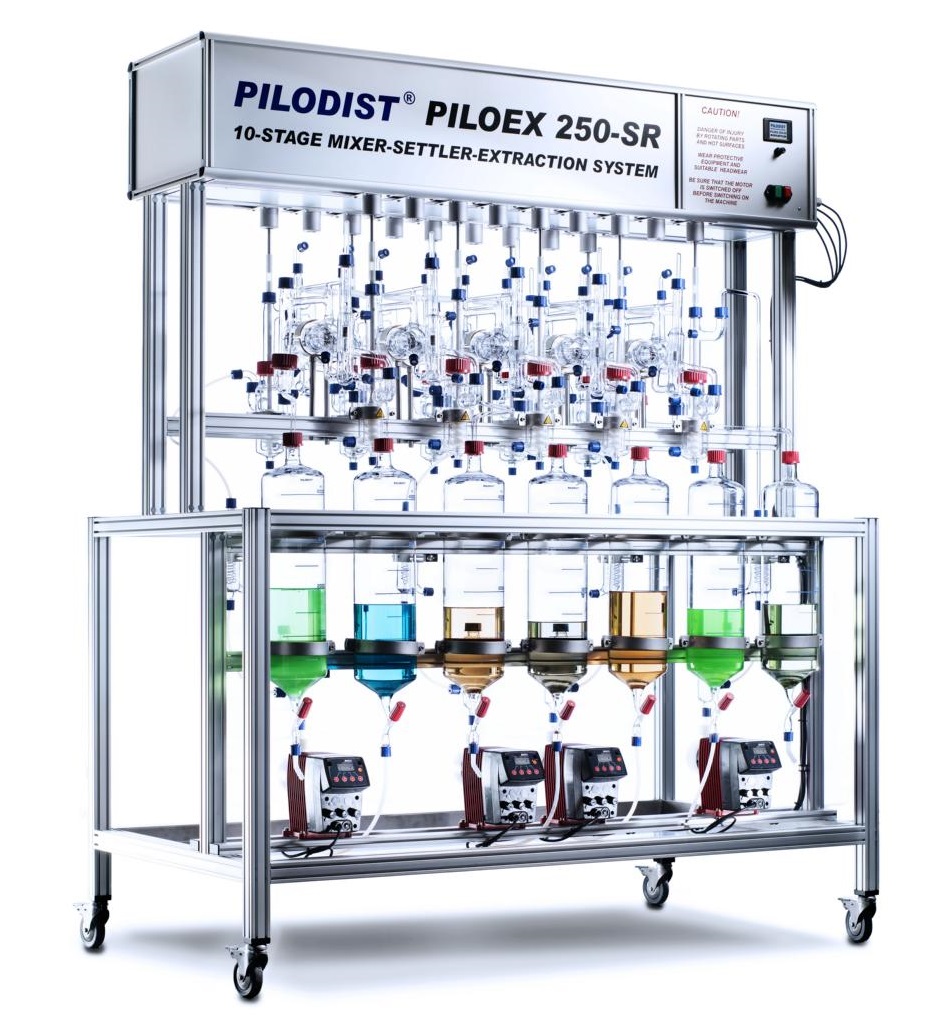

Mixer Settler extractror for liquid-liquid extration

This mixer-settler apparatus serves for studying liquid-liquid-extraction processes. One part of the component, which has to be separated from the liquid phase (raffinate phase) is extracted by means of a liquid solvent (extract phase). This component is concentrated in the solvent (extract phase from the extraction phase to extraction phase). The raffinate phase and the extract phase will be led through the unit in opposite directions. The advantage of the mixer-settler apparatus is the high efficiency of the exchange stages.

Each stage consists of a mixer with downstream settler. In the mixer the light and the heavy phase from the neighbouring stages are brought together, are intensively mixed and are simultaneously conveyed into the settler. Due to the intensive mixing the phases are divided into drops, so that the greater exchange surface, the substance transfer from one phase to another will be intensified. In the settler phases calm down and the continuous phases develop anew.

Together with the component, which is to be extracted, e.g. heavy phase, is the raffinate phase pumped from the raffinate store into the mixer of the last stage of the extractor. The solvent, e.g. light phase is pumped from the corresponding store tank into the mixer of the first stage of the extractor. Both phases, raffinate and extract are led into opposite directions through the extractor, the raffinate phase from the last stage and the extract phase from the first to the last extraction stage.

On it’s way to the apparatus the component which is to be extracted, is more and more separated from stage to stage. Simultaneously the solvent stream (extract phase) absorbes more and more of the extracted component. The raffinate phase from which the component has been extracted, leaves the extractor at the first stage and is collected in a collecting vessel. The extracted phase leaded with the extracted component leaves the extractor at the last stage and is collected in a collecting vessel.

Contrary to other separation methods, the extraction will not directly lead to pure components. The extract phase is e.g. to be separated in a downstream distillation/rectification into extracted component and solvent.

The advantage of the extraction is e.g. the lower consumption and the possibility of a primary separation of the components, which would not or would only be possible by distillation.

Applications

• metal salt extractions

• liquids with low surface tension

• difficult coalescence in dispersed phase

• variation of the resident time for phases in the extraction stages

• reactions occuring during the extraction procedure

• considerable variations of the density during extraction

Basic Equipment

1 bench-type frame for the complete extraction unit, mobile on rolls, including all

accessories as well as Teflon-lines and connections

4 extraction stages 250 ml content of each stage

2 series stirring devices with digital speed display

2 feed measuring vessels for light and heavy phase, graduated, with measuring device

(Flowmeter) and control valves

2 funnels

2 drain measuring vessels for light and heavy phase, graduated, with control valve

2 feed pumps for continuous adjustment of the throughput quantity between 0.2-5 l/h

2 pressure stabilising valves

2 pulsation dampers

Settler volume: 250 ml

Number of stages: 4; 6 or 10

Stage efficiency: approx. 95 %

Mains supply: 220 - 240 V, 50 - 60 Hz

Dimensions: 1250 x 1500 x 1000 mm (w x h x d)